Temperature will go down soon after the top temperature is achieved.

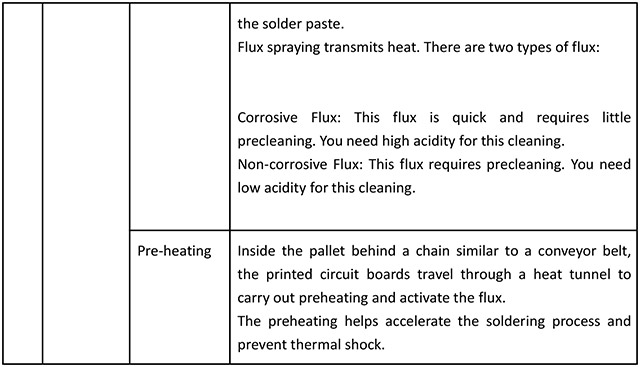

Too high a temperature may cause damage on surface mount technology (SMT) components or boards. Too low a temperature stops the solder paste from sufficiently reflowing Temperature control plays a crucial role in the reflow soldering process. This phase occurs when the peak temperature is achieved, enabling the solder paste to be melted and reflowed. Accordingly, temperature has to reach a level at which flux can be activated, or the flux fails to play its role in the soldering process. 4 Vreeland Road, Florham Park, NJ 07932, USA. USA, Asia, Europe to get a closer look at our reflow ovens / reflow soldering machines and get all of your questions answered. Similar to wave soldering, reflow soldering also depends on flux that has been contained in solder paste. Bifurcated Dual Lane / Dual Temperature Reflow Oven chamber allows 2 different thermal profiles to run simultaneously in the same reflow. Otherwise, soldering quality will be compromised. Second, it is responsible for expelling volatile solvents contained in solder paste. This step serves two purposes during reflow soldering.įirst, it allows boards to be assembled to consistently reach the required temperature to fully comply with thermal profiling. Real reflow soldering won’t start until those preparations have been made. Then, components are placed on pads by a pick-and-place machine. First, solder paste is accurately placed on each pad through a solder paste stencil. This process primarily contains two steps. After being cooled to room temperature, the board will be successfully assembled. As temperature reaches the peak in the wave soldering stage, it is reduced, which is called a cooling zone. Wave soldering profile conforms to a temperature curve. Components can be solidly bonded on boards. In a pallet along a chain similar to a conveyor belt, circuit boards travel through a heat tunnel to carry out preheating and activate flux.Īs temperature constantly rises, solder paste becomes liquid with a wave formed from the edge boards that travel above. Primary functions of solder flux include :ġ).Eliminating oxide from the metal surface of boards and component pins Ģ).Protecting circuit boards from secondary oxidation during the thermal process ģ).Reducing surface tension of solder paste Solder flux plays a crucial role in smooth implementation of soldering. The wave soldering process is composed of four steps:flux spraying, preheating, wave soldering, and cooling.Ĭleanliness of PCB surfaces is the basic element ensuring soldering performance, depending on functions of solder flux.

0 kommentar(er)

0 kommentar(er)